New Energy Insights

- Home /

- New Energy Insights /

- How to Increase Photovoltaic Cell Efficiency

Companies around the world are exploring ways to save money, while also decreasing the negative environmental effects they have on the planet. To find a solution, these companies are investing millions of dollars in research and development (R&D) to be self-sufficient and sustainable. Using green and renewable energy is a great way to reach these goals.

Studies show that green and renewable energy sources, like solar energy, are not only more efficient and reliable, but also effectively avoid contributing more pollution to the environment in comparison to energy derived from oil and gas. Solar energy is one of the largest and growing sectors in renewable energy, and it is predicted to be responsible for approximately 13% of energy production by 2030.14 Although solar energy effectively converts solar rays into usable energy, only 5% to 25% of the solar energy captured by photovoltaics (PV) is converted to usable energy. The rest is reflected or lost due to heat and other factors.15

Due to this low percentage of solar energy being captured by PV, multiple studies are being conducted to optimize energy potential and production. It is possible to increase the efficiency of photovoltaic cells by developing new technology. But the question remains: How can we increase solar panel energy production at a lower cost?

Using cooling techniques to improve solar panel efficiency

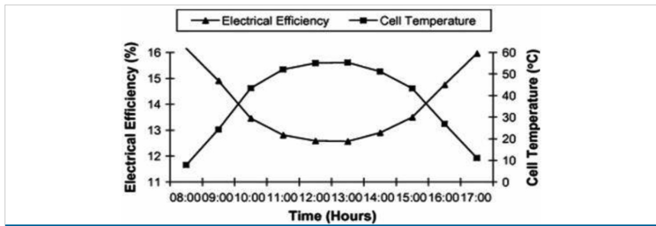

Electric efficiency in solar panels is inversely proportional to the temperature of the PV cells; this means that the higher the temperature, the less energy it produces (see Figure 1). 18

- A 1-degree Celsius increase in the temperature decreases the PV efficiency by 0.1%, consequently decreasing the power output by 0.45%.10

- Higher temperatures can also cause cracks in between the panels, creating a gap that invites moisture, which may shorten the circuit and create fire.10

- Elevated temperatures cause damage to solar panels, which require constant maintenance, leading to higher costs.10

Figure 1- The correlation between electrical efficiency and cell temperatures. 18

An obvious solution is to cool the solar panels down to maintain a more sustainable temperature allowing for optimal energy output. But what is the best way to cool them down?

What is the best way to cool down solar panels?

Cooling down solar panels has the potential to create a major positive impact on the productive output of the panels. This will inevitably lead to a decreased overall cost associated with solar development. There are several effective methods, both active and passive, that have proven to be successful in cooling PV cells.

Various cooling methods for PV systems have been researched, such as cooling with liquids, phase change materials, and air. These cooling methods are used actively or passively depending on the required application. Active cooling involves using pumps or blowers to remove excess heat absorbed by the PV cell by circulating fluid or air on the front or back of the PV panel. Active cooling is more effective in removing heat from the panel, resulting in greater efficiency, but it has issues with parasitic power consumption and system maintenance costs. Passive cooling, on the other hand, does not require any parasitic power consumption for cooling because it relies on natural conduction, convection, or radiation for heat removal, resulting in minimal operation and maintenance costs.10

- Liquid: Water is more effective than gas at removing heat from the system due to its high thermal conductivity, making liquid-based cooling the preferred method for higher temperatures. Water has the highest thermal conductivity of any liquid, and its thermal conductivity only decreases at temperatures above 130°C.

- Phase Change Material: PCM-based cooling materials have drawbacks such as incompatibility with plastic pipes/containers, flammability, and toxicity.

- Air: Ground Couples Central Panel Cooling system (gc-cpcs) - is a method that blows ambient air through the rear surface of the solar panel. The cooled air is distributed to each module through a pipe. To run this system, power will be provided separately from the PV panel. 16

After comparing the available methods, research has focused and elaborated on the liquid cooling method using water.

Water cooling technique

PV panel temperatures may increase up to 50 degrees Celsius during peak hours, reducing energy production. Water aided by a pump can reduce the temperature by 15 degrees.19 Although this method has been used since the preliminary stages of adoption of solar energy production, it has negative impacts on the environment due to elevated levels of water consumption. In an experiment, several PV cells were submerged in water between 0 to 50 cm deep and their performance was observed. This increased the solar panel efficiency by up to 20 percent. 21 Not only did submerging solar panels in shallow water increases efficiency, but it also protects the PV panels from dust, which is one cause of decreased efficiency. 21 Since solar energy production has a positive impact on the environment, many pro-environment activists argue that the use of water for cooling method can disrupt the positive reputation of Solar energy. However, water can be recycled and reused.

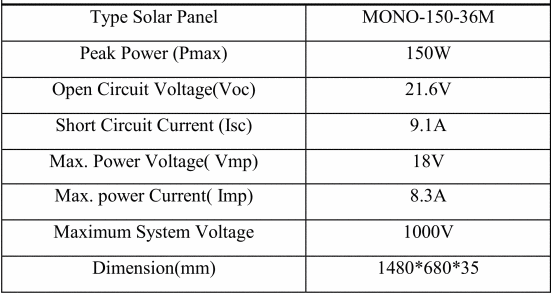

To demonstrate the effectiveness of water-cooling methods, experiments were conducted using a SAKO Solar Module (Figure 2).

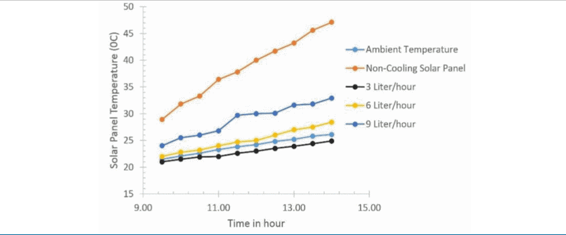

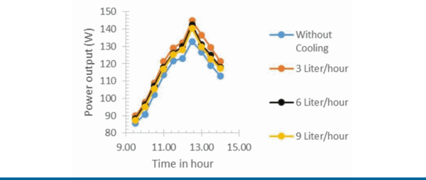

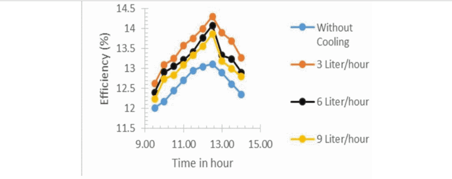

In this experiment the authors used water as a coolant for their PV cells and compared the outputs of data between non-cooled PV cells vs the cooled ones. Figure 3 shows the change of value of the temperature, Figure 4 shows the change in power output, and Figure 5 shows the change in value of the PV cells' efficiency. 17

Figure 2-(A. M. Ahmed and S. Hassan Danook, 2018)

Figure 3- (A. M. Ahmed and S. Hassan Danook, 2018)

Figure 4- (A. M. Ahmed and S. Hassan Danook, 2018)

Figure 5- (A. M. Ahmed and S. Hassan Danook, 2018)

Electrostatic cooling technique

As solar panel plants grew and many countries adopted them, a few problems started emerging, including dust and humidity that decreased efficiency. One of the largest solar panels harvesting extensions is in the Mojave desert near Las Vegas. The Mojave desert receives twice as much sunlight as other parts of the United States, making it an ideal place to harvest solar energy. This plant produces around 280 megawatts of energy, providing for over 75 thousand homes.22 Unfortunately, one of the problems solar panels are facing in sandy desert areas is dust landing on their surface, resulting in a layer of crust. This layer of crust inhibits the sun’s rays from fully penetrating the panel, causing a decline in the efficiency of the affected solar panels. (Figure 6)

Figure 6 Soiled PV panels installed in Doha, Qatar. (Courtesy Bing Guo, Texas A&M University at Qatar)

To tackle this problem researchers proposed a solution that wipes down sand from solar panels by using an innovative technology called electrostatic cleaning method. This new detachable electrostatic cleaning system is being developed to address the limitations of existing systems. This new system can be realized with a low initial cost, does not reduce the output power of the PV panel, and is applicable for existing plants. The system consists of parallel screen electrodes set in a frame, to which a high alternating voltage is applied. The alternating electrostatic field near the electrodes agitates dust particles on the panel surface, which are then ejected through the upper screen electrode openings. The ejected dust then falls downward along the inclined panel due to gravitational force. This system has been tested on dust collected from a solar panel in Doha, Qatar and has demonstrated satisfactory performance. The development of this system shows promise for more cost-effective and efficient cleaning of solar panels in the future.2

Using stain detection to improve solar panel efficiency

Stains on solar panels cause thermal spots that can completely damage the panel, so detecting stains on solar panels in a timely manner is crucial. Researchers at the Shanghai University of Electric Power list several methods to detect stains on PV cells before they cause irreversible damage.20 A few of those methods include:

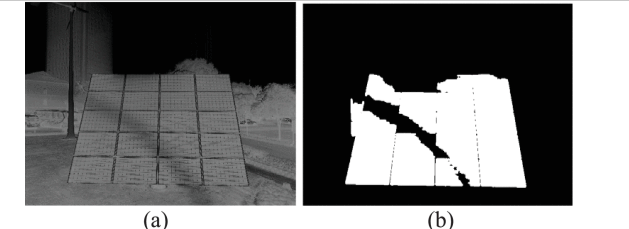

Spot elimination method: Optical images are commonly used to obtain an image of the photovoltaic panel to detect stains on it. However, shooting conditions such as lighting or shading can create bright spots or dark spots on the image, making it difficult to distinguish the photovoltaic panel from the surrounding environment during image preprocessing. For this reason, spots such as shade or light spots on the panel should be eliminated. To address the gray level of the image should be linearly transformed. A one-dimensional linear function is used for this transformation, with fA as the slope, fB as the Y-intercept, DA as the input image's gray level, and DB as the output image's gray level. The dark area of the image is brightened, and the bright area is darkened by setting fA<0. The processed image is then subjected to binarization, hole filling, and small area connected region deletion to remove the background and retain only the photovoltaic panel. The contrast of the image is also decreased to reduce the difference between the spot brightness and the background brightness, minimizing its influence on the background elimination operation. Finally, the photovoltaic panel area is extracted from the image by removing the background part, as shown in Figure 7.20

Figure 7

After any spots have been eliminated from the image, the "image correction" method is applied.

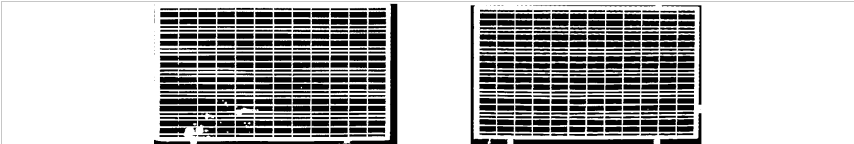

Image Correction method: The images of solar photovoltaic panels often appear tilted due to external environmental factors and equipment limitations during the shooting process. Thus, it becomes essential to rectify these images before detection. By doing so, the size of each panel can be made uniform, reducing the difficulty of detection. Moreover, it ensures that the same detection method is suitable for each panel.Image segmentation method: It is important to segment the panels into separate sections and conduct individual analysis to enhance the accuracy of stain detection in solar photovoltaic panels. This is done by first converting the corrected image into a binary image. The distribution of black and white pixels in the binary image is then used to create histograms along the horizontal and vertical directions using the summation function. There are two types of images segmentation, horizontal and vertical segmentation.20

-

- To perform vertical segmentation on a photovoltaic panel image, a histogram is used to sum the pixel points in the horizontal direction, with "1" representing white pixels and "0" representing black pixels. By analyzing the histogram, the area with the highest pixel count can be identified, and the average value can be obtained based on the number of pixels. This allows the left and right panels to separate, as the photovoltaic panel has already been corrected for perspective and has a relatively uniform pixel distribution. The "max" function is used to obtain the maximum pixel count and its position in the horizontal summation matrix "a" and construct a new matrix "P" based on the positions of these maximum values in "pi" if there are multiple maximum values.20

- To perform horizontal segmentation on a photovoltaic panel image, the histogram is analyzed to identify the gaps between each panel. These gaps are characterized by a higher proportion of black pixels, while the areas to the sides have a higher proportion of white pixels. Using the "max" function, the segmentation coordinates can be obtained. These coordinates are then used as the height parameter when calling the "imcrop" function to obtain individual images of each solar panel. The segmentation result is displayed in Figure 8.

Figure 8-Image segmentation results (Wen et al 2021)

Stain Detection Method

After segmenting the photovoltaic panels in an image, it is necessary to detect any stains present on the panels. However, since the image only contains information about the lines of the solar photovoltaic cells and the stains themselves, it is important to distinguish between the two to accurately identify the stains. This can be achieved by expanding the lines in the image to ensure all relevant information is captured, and then removing any small objects that are not stains.

Once the stains are identified, a red rectangular frame is used to calibrate their range. The position of the white pixels in the image is determined using the find function, and the maximum and minimum four points along the X and Y axes are used to create a rectangular frame around the stains. This accurately marks the stains in the image.

HALCON-based solar panel stain detection

Solar panels are made of photovoltaic cells that are produced in a sophisticated environment. They require detailed inspections and tests before being sold and connected to the grid. Many solar panel faults are caused by a lack of proper inspection during production. Detecting cracks in a solar panel is one of the most important steps in determining if a solar panel is viable. Cracks are not visible to the naked eye; they are macroscopically small, and they can cause unexpected faults. Many companies rely on manual crack detection which Guanghua Yao and Xuncheng Wu describe as “Boring and makes people slack” in their article “HALCON-Based Solar panel Crack Detection.” When humans attempt manual detection, they rely on existing standards and common sense and often only pay attention to more obvious defects. 4

To make fault detection more accurate the authors suggest HALCON software. HALCON is a software toolkit for machine vision and image processing that has been developed by MVTec in Germany. It provides a comprehensive and adaptable integrated development environment for machine vision, offering over 1,800 operators for image processing and a robust data management core that supports mathematical operations. HALCON stands out from other image processing software due to its extensive and open driver links, customizable user interface, independent and effective image processing language, making it an ideal choice for engineers engaged in the design and research of image processing algorithms.4

- Classification: HALCON's deep learning capability includes image classification, which can distinguish between different items in an input image and output specific class or classes of the image.4

- Object Detection: HALCON's deep learning method includes object detection, which can identify multiple objects in a picture and locate different objects by providing a bounding box.4

- Semantic Segmentation: HALCON's deep learning technique includes semantic segmentation, which assigns each pixel in the image to a specific object class. This method is useful for highlighting regions of interest in an image.4

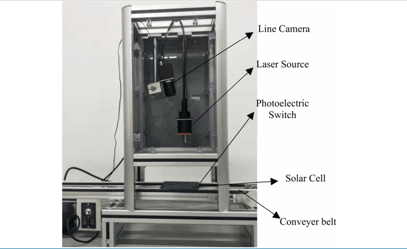

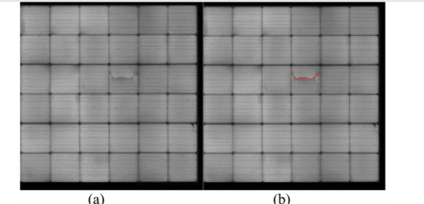

To successfully implement this software the team built an experimental device (Figure 9) to detect cracks on a solar panel. They put a solar device and tested it. As it can be seen from the test result picture, (Figure 10) that the crack is successfully detected. The cell size used for the test in this experiment was 160 mm * 160 mm and the thickness is 160-180µm. The productivity of this experimental equipment can reach 3,600 pieces/hour, the over-judgment rate is ≤10%, the missed rate is ≤0.2%.

This experiment shows that the experimental equipment can stably detect cracked cells. This helps decrease the rate of defective products during the later stages of production. This, in turn, enhances the overall quality of solar cells, reduces energy waste, and minimizes labor costs.

Figure 9 (Halcon-based Solar Panel Crack Detection, G. Yao, and X. Wu, 2019)

Figure 10 (Halcon-based Solar Panel Crack Detection, G. Yao, and X. Wu, 2019)

The solar industry has continued to be successful year after year. Its continued success is dependent on methods like these that help innovate and improve how efficiently our technology works.

Need help Operating and Maintaining your solar garden? Visit our partners at Energy Support Services!

-----------------------------------------------------------------------

References

- M. Singh, J. Singh, A. Garg, E. Sidhu, V. Singh, and A. Nag, (2016) Efficient autonomous solar energy harvesting system utilizing dynamic offset feed mirrored parabolic dish integrated solar panel, International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), 2016, pp. 1825-1829, doi: 10.1109/WiSPNET.2016.7566456

- H. Kawamoto and M. Kato(2018), Electrostatic Cleaning Equipment for Dust Removal from Solar Panels of Mega Solar Power Generation Plants, IEEE (Institute of Electrical and Electronics Engineers) 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), 2018, pp. 3648-3652, doi: 10.1109/PVSC.2018.8547468.

- M. Gabor et al.(2019). Mounting Rail Spacers for Improved Solar Panel Durability," IEEE 46th Photovoltaic Specialists Conference (PVSC), pp0131-0135, doi: 10.1109/PVSC40753.2019.8981256.

- Yao and X. Wu,(2019)"Halcon-Based Solar Panel Crack Detection,", 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM) pp. 733-736, doi: 10.1109/WCMEIM48965.2019.00154.

- P. Ramirez-Del-Barrio et al.,(2017), Sustainable development through the use of solar energy for productive processes: The Ayllu Solar Project," 2017 IEEE Global Humanitarian Technology Conference (GHTC), 2017 pp. 1-8, doi: 10.1109/GHTC.2017.8239310.

- T. V. Myasnikova, A. A. Kirillova, S. P. Ivanova, O. V.Sveklova and O. A. Nadezhdina,(2020)Simulation of Solar Energy Photovoltaic Conversion, International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), pp. 1-4, doi: 10.1109/REEPE49198.2020.9059149.

- "To Fight Big Pollution, We Need Big Solar". Earth Island Journal, 2021, https://www.earthisland.org/journal/index.php/magazine/entry/bigsolar/.

- V. N. Amalnath and R. Zachariah,(2017)A simple control unit for temperature dependent forced water cooling in solar CPV/T collector, IEEE International Conference on Intelligent Techniques in Control, Optimization and Signal Processing (INCOS), 2017, pp. 1-5, doi: 10.1109/ITCOSP.2017.8303147.

- Koerth-Baker, M. (2021, May 03). Shining light on the cost of Solar Energy. Retrieved December 07, 2021, from https://www.nationalgeographic.com/science/article/101105-cost-of-solar-energy

- U. Nasir, Saif-ur-Rehman, A. Waqas and R (2020). Majeed. Improving Photovoltaic Module Efficiency Using Back Side Water-Cooling Technique.IEEE 23rd International Multitopic Conference (INMIC), 2020, pp. 1-6, doi: 10.1109/INMIC50486.2020.9318093.

- Y. Wang, R. Tummala, L. Q. Guo, W. Zhou, and M. Tao.(2009) Solution-processed spherical surface textures on amorphous silicon solar cells. 34th IEEE Photovoltaic Specialists Conference (PVSC), 2009, pp. 001771-001774, doi: 10.1109/PVSC.2009.5411470

- Y. A. Al-Wajih, M. F. Mysorewala, A. A. Mohammed and S. Mostafa. (2020) Improving the Performance of Solar Panels by Automated Water Cooling System and IoT. First International Conference of Smart Systems and Emerging Technologies (SMARTTECH), 2020, pp. 134-137, doi: 10.1109/SMART-TECH49988.2020.00042.

- S. A. Marathe and B. P. Patil,(2020). Mechanisms for Improving the Productivity of the Existing Photovoltaic Panels: A Review.International Conference on Computational Performance Evaluation (ComPE), 2020, pp. 087-090, doi: 10.1109/ComPE49325.2020.9200005.

- Solar energy could power 13 of the world by 2030. Solar Energy Could Power 13 of the World by 2030. (2016, June 22). Retrieved March 21, 2023, from https://www.irena.org/news/articles/2016/Jun/Solar-Energy-Could-Power-13-of-the-World-by-2030

- Ali Sayigh,(2013) Comprehensive Renewable Energy, Volume 1(2013), 3.08- Photovoltaic/Thermal solar Collectors, Y. Tripanagnostopoulos pp. 255-300

- N. Sasidharan, W. Ongsakul, M. P. Varghese, V. S. Anooja, and R. Akhila,(2018) "Efficient improvement of solar photo voltaic system using artificial cooling methods," 2018 International Conference on Power, Signals, Control and Computation (EPSCICON), Thrissur, India, 2018, pp. 1-6, doi: 10.1109/EPSCICON.2018.8379593.

- A. M. Ahmed and S. Hassan Danook, (2018) "Efficiency improvement for solar cells panels by cooling," 2nd International Conference for Engineering, Technology and Sciences of Al-Kitab (ICETS), Karkuk, Iraq, 2018, pp. 39-42, doi: 10.1109/ICETS.2018.8724625.

- J. Siecker, K. Kusakana and B. P. Numbi, (2017), A review of solar photovoltaic systems cooling technologies" in Renewable and Sustainable Energy Reviews, Elsevier Ltd, vol. 79, pp. 192-203,

- M. I. B. Sheikh, S. bin A. Kashem, and T. Choudhury, (2017), Enhancing solar power generation using gravity and freshwater pipe, IEEE International Conference on Mechatronics (ICM), Churchill, VIC, Australia, pp. 266-271, doi: 10.1109/ICMECH.2017.7921115.

- W. WEN, S. LI, F. ZHOU, M. LI, Q. XIE, and S. Chen, (2021), Stain detection method of solar panel based on spot elimination, IEEE 2nd International Conference on Big Data, Artificial Intelligence and Internet of Things Engineering (ICBAIE), Nanchang, China, pp. 820-824, doi: 10.1109/ICBAIE52039.2021.9390021.

- R. Lanzafame, S. Nachtmann, M. Rosa-Clot, P. Rosa-Clot, P. F. Scandura, S. Taddei et al., 2010"Field experience with performances evaluation of a single-crystalline photovoltaic panel in an underwater environment", IEEE Transactions on Industrial Electronics, vol. 57, pp. 2492-2498.

- Antonio J. Gallego a, et al. 2022 “Model Predictive Control of the Mojave Solar Trough Plants.”Control Engineering Practice, Pergamon, reader.elsevier.com/reader/sd/pii/S0967066122000491?token=6C9ACBD033FA9229D3BE26D52EC3DC0EDB9C254677D59D2DAA975D0777EAC55337FA9D6E76B3C9C3EB55805B8345238C&originRegion=us-east-1&originCreation=20230406203942.

Stay up-to-date with New Energy Equity by joining our mailing list.